Complexity, Accuracy, Reliability

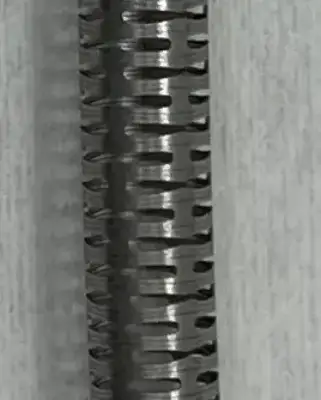

Flexible laser cut hypotubes are used in delivery systems for minimally invasive interventions due to their combination of push, trackability, torque and kink resistance. These performance characteristics have established the hypotube as the device shaft of choice for percutaneous transluminal coronary angioplasty (PTCA) procedure applications.

Recognising these superior performance benefits, medical device manufacturers have adopted flexible laser cut hypotubes in new procedure application areas, such as abdominal aortic aneurysm (AAA), neurology, peripheral vascular interventions and imaging.

Hypotubes are generally produced from 300 series stainless steel tubing, commonly 304 stainless steel (1.4301) and also in 316 (1.4401), 17-7PH (AMS 5528) and Nitinol.

With laser cutting patterns along the hypotube the medical device design engineer can tailor the flexibility from the proximal to distal end. Also the laser cut pattern can determine the wide range of performance characteristics.

Finding the right hypotube for your device application

XL Precision Technologies now offers various hypotube supply options to meet our customers’ ever increasing design demands. We offer four separate hypo tube products. We can meet your design requirements of Speed, Performance & Cost.

Flexi Hypotube

Working with our extensive network of approved tube mill suppliers we can source conventional hypo tubes in 304 or 316 stainless steel meeting standard mechanical properties and cost competitiveness.

Flexi Express Hypotube

From our own tube stock, or through our supply partners with a vast range of tube sizes available, our development engineers can have tubing in hand within 1 week to start cutting your hypotube design.

Flexi Match Hypotube Service

We can match the mechanical characteristics of a sample of your existing base hypotube, reducing the risk of supply transfer mid-development or production. A full report can be supplied outlining key mechanical properties for approval.

Flexi Plus Hypotube

We offer tubing with higher elongation, usually around 8%. This improves the ductility and kink resistance of the hypotube in your device.

Flexible Laser Cut Hypotubes

XL Precision Technologies has experience with supplying various laser cut patterns on hypo tubes to provide our customers with the right flexibility solution to their cardio & endo vascular delivery device needs.

- Continuous Spiral Cut Pattern

- Bespoke Cut Patterns

- Interrupted Spiral Cut Patterns

- Radial Cut Patterns

Additional Features

XL Precision Technologies’ laser cutting capabilities allow customers to develop various features to enhance their overall hypo tube design.

- Off centre laser cutting – provides design engineers with more design option possibilities

- Ablation into the tube wall, knurl or radial rung patterns – deal for improving over moulding/bonding performance

- Unique features for deployment and assembly functionality – Windows, formed tabs and drill holes

Capabilities

What We Can Offer

Laser Technology

Laser Technology

Micro Machining

Micro Machining

Clean Room Assembly

Clean Room Assembly

If you would like to know more about

how XL-PT can help you, get in touch.

If you would like to know more about how XL-PT can help you, get in touch.

XL Precision Technologies specialise in the manufacturer of precision micro-components, complex tubular components and sub-assemblies for the medical device industry.