Utilising technology to delivery your requirements

XL Precision Technologies operates full 4D design and machine programming systems. We can interpret customer requirements via drawings or computer models, and quickly establish feasibility and delivery plans.

We utilise a proprietary combination of laser technology, EDM wire erosion and sink erosion, 5-axis CNC machining and 3D Metal Printing Technology to ensure we can uniquely meet our customers’ high expectations in component manufacturing.

Laser

Machining

CNC

Machining

EDM

Wire & Sink

3D Metal

Printing

XL Precision Technologies - Capabilities and Expertise

Finding the right solution through the selection of appropriate technology.

Wire EDM (Electrical Discharge Machining) is a high precision process that uses a computer-controlled, electric plasma field, conducted through fine wire, to cut profiles and feature in all metal alloys and other conductive materials. The surface finish can be refined to eliminate any further polishing processes.

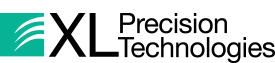

Sink EDM utilises the same technology as wire EDM but using specific shape and configuration electrodes to define the machined feature or dimension. XL Precision Technologies offers the latest technology and capability in extremely accurate and economic applications.

We offer multiple-axis milling and turning capability to provide optimum cost and capability solutions.

We also offer a unique micro flat bed laser cutting capability, developed in house at XL PT for various medical component needs. Holes of 0.030mm diameter and kerf widths <0.015mm are achieved.

Within our micro-machining capabilities our Laser Technologies hold a key element in our ongoing success. With our laser tube cut cutting capabilities we can produce extremely small and complex tubular components, used in Cardio and Neuro vascular deployment devices.

EDM features can be combined with laser machined and conventionally machined components and assembled using laser micro-welding technology. These combinations of process significantly broaden the applications and solutions available. Universal modelling and programming software ensures design integrity is maintained. To further increase the productivity, a low profile, universal, work holding tooling system has been developed. By setting the work piece away from the machine we improve flexibility and increase machine utilisation; all of which helps us to be more competitive in the market.

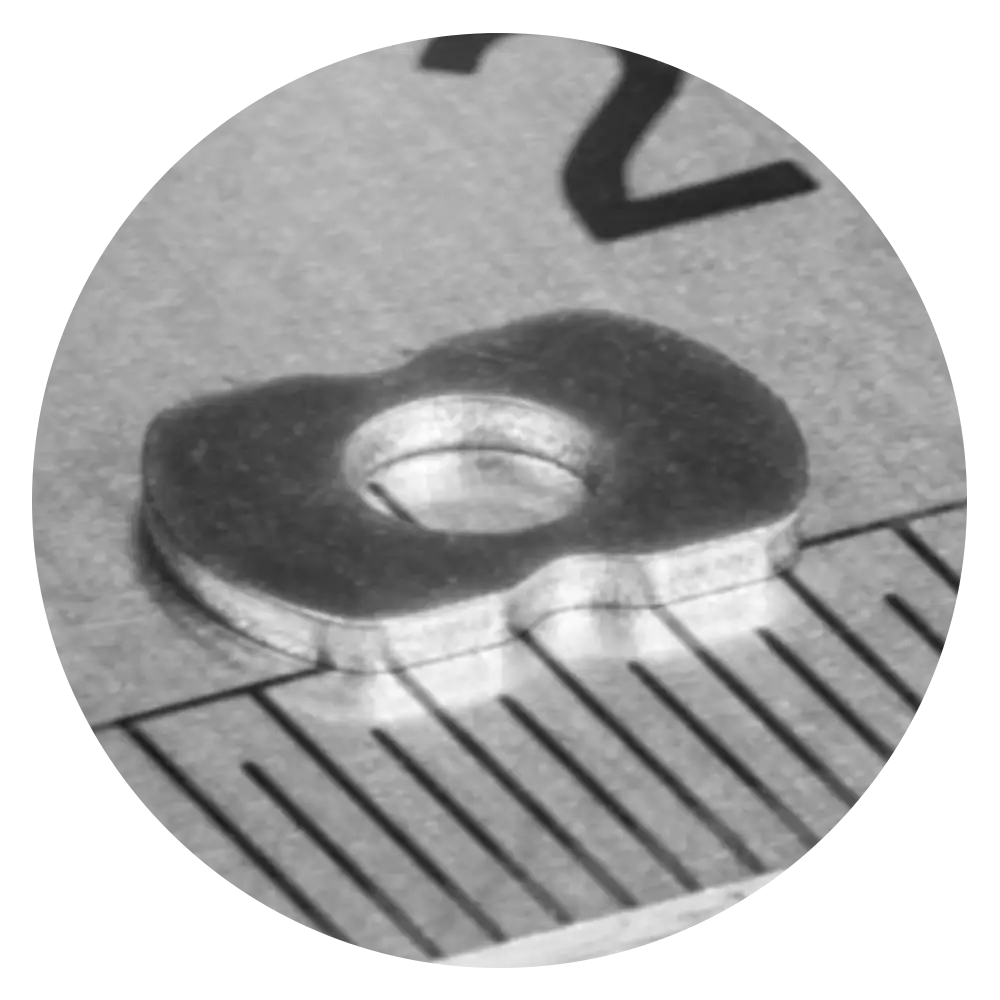

Our new 3D metal printing capability offers high definition for micro-machined medical components. Using our existing micro-machining capabilities allows us to fully utilise 3D metal printing;

- Adding extra machined features with EDM, milling and Laser

- Post printing surface treatment, tumbling and electro-polishing

See more

Our range of capabilities beyond Micro Machining

Laser Technology

Laser Technology

Clean Room Assembly

Clean Room Assembly

If you would like to know more about

how XL-PT can help you, get in touch.

If you would like to know more about how XL-PT can help you, get in touch.

XL Precision Technologies specialise in the manufacturer of precision micro-components, complex tubular components and sub-assemblies for the medical device industry.